Compatible consumables offer significant cost advantages for distributors and service providers, but bulk purchasing without proper evaluation can lead to quality issues, customer complaints, and financial losses. Before committing to large orders of toner cartridges, ink cartridges, drum units, or developer units, it is essential to carry out structured testing and evaluation. A systematic approach helps ensure product reliability, compatibility, and long-term performance.

Understand the Target Machine Models

The first step in evaluation is identifying the exact copier and printer models for which the consumables are intended. Even within the same brand, slight variations in machine design can affect compatibility. Confirm model numbers, firmware versions, and regional differences that may impact performance.

Testing should always be conducted on the actual machines used by end customers. Relying only on supplier test data is not sufficient for bulk purchasing decisions.

Inspect Physical Build Quality

Before installation, visually inspect the consumables for manufacturing quality. Check the casing, seals, gears, and connectors for defects or irregularities. Toner cartridges should have smooth gear movement and proper sealing, while ink cartridges should show no signs of leakage or deformation.

For drum and developer units, inspect the surface condition, protective covers, and assembly accuracy. Poor build quality is often an early indicator of inconsistent performance and reduced lifespan.

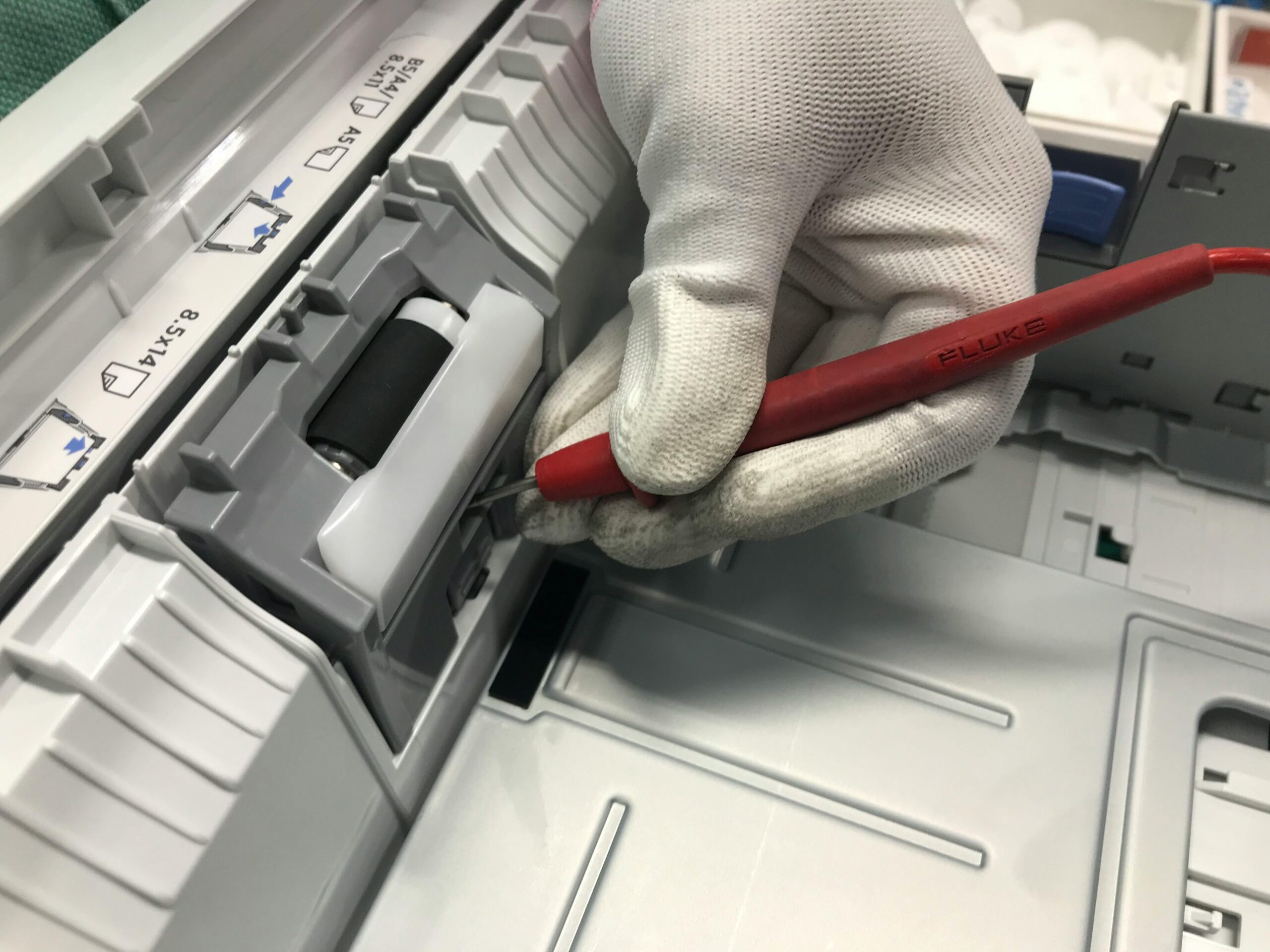

Perform Initial Installation Testing

Proper installation is critical to accurate evaluation. The cartridge should fit smoothly without forcing or adjustment. Difficulty during installation may indicate dimensional inaccuracies.

Once installed, confirm that the machine recognizes the consumable without error messages. Compatibility issues at this stage often point to chip problems or incorrect design.

Evaluate Print Quality from the First Output

Print test pages immediately after installation to evaluate initial output quality. Key factors to assess include image sharpness, density consistency, background cleanliness, and color accuracy for color devices.

Compare the results with OEM consumables under the same conditions. Any significant deviation in print quality should be investigated before proceeding further.

Conduct Stability and Consistency Testing

Initial prints may appear acceptable, but performance over time is more important. Run extended print tests to evaluate consistency across multiple pages. Look for gradual fading, streaking, uneven coverage, or background shading.

For service providers, testing under real workload conditions provides the most reliable results. Consumables should perform consistently throughout the test cycle without frequent adjustments or cleaning.

Monitor Toner or Ink Yield

Yield testing helps determine whether the consumable delivers the expected number of pages. While exact OEM yield matching is not always required, significant underperformance affects cost calculations and customer satisfaction.

Track page counts under standard coverage conditions and compare results with supplier claims. Reliable suppliers provide realistic yield data rather than exaggerated figures.

Assess Machine Impact and Wear

Compatible consumables should not negatively affect the copier or printer. During testing, monitor the machine for abnormal noise, excessive toner buildup, or increased error rates.

Pay special attention to drum and developer interaction. Poorly matched consumables can accelerate wear on internal components, leading to higher long-term maintenance costs.

Evaluate Packaging and Logistics

Packaging quality is often overlooked but plays a vital role in bulk purchases. Proper packaging protects consumables during transport and storage. Check for secure sealing, clear labeling, and adequate protective materials.

For bulk orders, consistent packaging standards reduce damage rates and simplify inventory handling.

Review Supplier Support and Warranty

Technical support and warranty coverage are critical when purchasing compatible consumables in large volumes. Reliable suppliers provide clear warranty terms, batch traceability, and responsive after-sales support.

Before placing bulk orders, confirm how quality issues are handled and whether replacement or compensation policies are in place.

Conduct Small Batch Trials Before Scaling Up

A pilot order is the final and most important step. Start with a small batch and deploy the consumables across multiple machines or customers. Gather feedback from technicians and end users before committing to larger volumes.

This approach minimizes risk and builds confidence in the product and supplier relationship.

Conclusion

Testing and evaluating compatible consumables before bulk purchase is essential for protecting product quality, customer satisfaction, and business reputation. By inspecting build quality, conducting real-world performance testing, monitoring yield and machine impact, and working with reliable suppliers, distributors and service providers can make informed purchasing decisions.

A structured evaluation process reduces risk and ensures that compatible consumables deliver consistent, cost-effective performance at scale. For professional guidance and reliable compatible consumables, The Omni CopierTech Co., Ltd. is ready to support your bulk purchasing needs.