Printing remains an essential part of daily operations for many businesses, service providers, and organizations. However, rising consumable costs, maintenance expenses, and inefficiencies often place pressure on budgets. The challenge is not simply to reduce printing costs, but to do so without sacrificing print quality, machine reliability, or customer satisfaction.

By adopting the right strategies and making informed decisions about consumables, workflows, and maintenance, it is possible to achieve significant cost savings while maintaining consistent, professional output.

Understand Where Printing Costs Come From

To control costs effectively, it is important to first understand what drives them. Printing expenses typically include toner or ink cartridges, drum and developer units, spare parts, paper, machine maintenance, and downtime caused by poor-quality supplies. In many cases, consumables account for the largest share of total printing costs.

Reducing expenses does not mean choosing the cheapest option available. Instead, it requires evaluating the total cost of ownership, including yield, reliability, and impact on machine performance.

Choose High-Quality Compatible Consumables

One of the most effective ways to reduce printing costs is to use high-quality compatible or remanufactured consumables. OEM cartridges are designed for optimal compatibility and performance but often come at a premium price. Well-manufactured compatible cartridges, produced to meet OEM specifications, can deliver similar print quality and page yield at a lower cost.

The key is supplier selection. Not all compatible consumables are equal. Reputable manufacturers conduct strict quality control, real-machine testing, and batch inspections to ensure consistency. Poor-quality cartridges may cause leakage, background issues, or increased wear on machines, leading to higher long-term costs.

For distributors and service providers, working with a reliable supplier helps ensure that cost savings do not result in increased complaints or maintenance issues.

Match Consumables to Actual Printing Needs

Many businesses overspend by using high-end consumables for low-demand printing tasks. For example, internal documents may not require the same print density or color accuracy as customer-facing materials. Matching consumable quality and specifications to actual usage needs can significantly reduce costs without affecting perceived quality.

High-yield cartridges are another effective option for offices with large print volumes. While the upfront cost may be higher, the lower cost per page and reduced replacement frequency often result in overall savings.

Control Print Volume Through Smart Policies

Reducing unnecessary printing is one of the simplest cost-saving measures. Implementing basic print management practices—such as default duplex printing, grayscale settings for internal documents, and controlled access to color printing—can lower consumable usage significantly.

Encouraging digital workflows, document sharing, and electronic approvals also reduces reliance on printed materials. For organizations managing multiple devices, centralized print policies help ensure consistent cost control across departments.

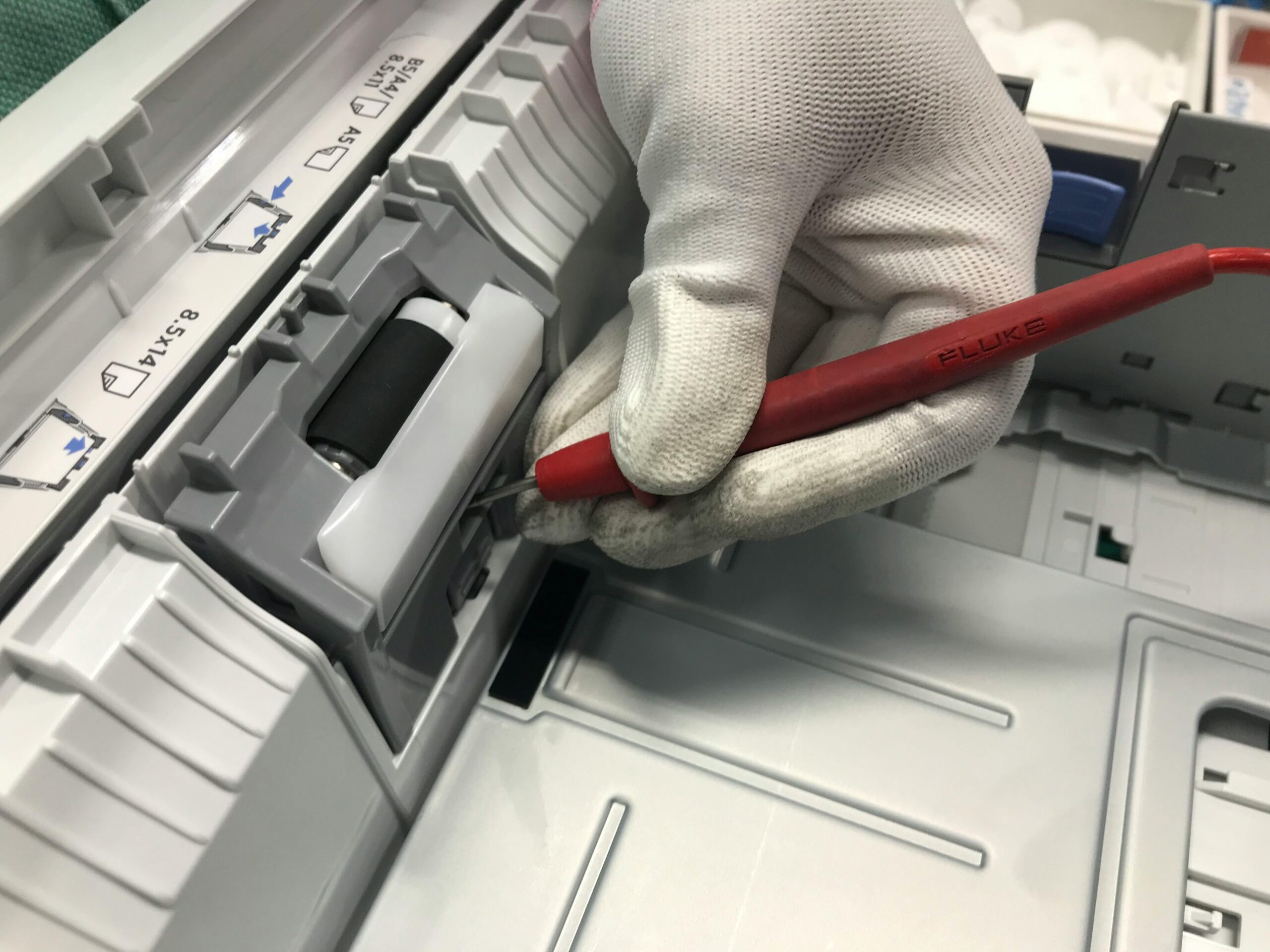

Maintain Equipment Properly

Poor maintenance can increase printing costs even when high-quality consumables are used. Dirty rollers, worn drums, or misaligned components can cause streaks, reprints, and wasted toner or ink. Regular maintenance helps maintain print quality and extends the life of consumables and machines.

Service providers should educate clients on preventive maintenance schedules, including timely replacement of drum units, developer units, and worn spare parts. Proper maintenance reduces downtime and avoids costly repairs caused by neglected components.

Use the Right Paper for the Job

Paper quality has a direct impact on toner and ink consumption. Paper that is too rough, too smooth, or outside recommended specifications can cause poor toner adhesion, smudging, or excess toner usage. Using paper that meets manufacturer guidelines helps ensure efficient toner transfer and consistent results.

Bulk purchasing of standard, compatible paper types can also reduce costs while maintaining acceptable print quality for most business applications.

Reduce Waste Through Testing and Standardization

For distributors and service providers, testing consumables before large-scale deployment helps prevent costly issues later. Standardizing on a limited number of tested, reliable models reduces complexity, training requirements, and troubleshooting time.

Avoid mixing consumable types unnecessarily. Using consistent toner, drum, and developer combinations that are known to work well together minimizes compatibility issues and reduces waste from failed prints or premature replacements.

Consider Long-Term Supplier Partnerships

Short-term savings from switching suppliers frequently can lead to long-term costs caused by inconsistent quality. Building long-term partnerships with reliable consumable suppliers often results in better pricing, stable quality, technical support, and flexible ordering terms.

Suppliers with OEM and ODM capabilities can also provide private labeling and customized solutions, allowing distributors to build their own brands while maintaining cost control.

Balance Cost Savings with Quality Expectations

Reducing printing costs should never come at the expense of professionalism. End users expect clear text, consistent color, and reliable output. The goal is not the lowest possible cost, but the best balance between cost, quality, and reliability.

High-quality compatible consumables, proper maintenance, controlled print policies, and trusted suppliers together create a sustainable approach to cost reduction.

Conclusion

Lowering printing costs without compromising quality is achievable with the right strategy. By choosing reliable compatible consumables, managing print volume wisely, maintaining equipment properly, and working with trusted suppliers, businesses and service providers can significantly reduce expenses while maintaining consistent, professional results.

In a competitive market, cost efficiency combined with quality reliability provides a strong advantage. Making informed decisions today leads to long-term savings, fewer disruptions, and higher customer satisfaction tomorrow.